What is Grounding?

Grounding in powder coating is the process of establishing a strong electrical connection between the object being coated and the ground. This connection ensures that the powder particles properly attract to the surface, enabling an effective and consistent coating process.

Why Grounding is Important?

Proper grounding is essential for maintaining the electrostatic charge during the powder coating process. This allows the powder particles to be attracted to the grounded object, ensuring an even and uniform coat. Without effective grounding, powder may fail to attract correctly, resulting in an uneven coating and reduced transfer efficiency, leading to lower-than-desired film builds.

Additionally, poor grounding can create safety hazards, such as arcing, which can damage equipment and pose risks to operators.

How Does Grounding Work in Powder Coating?

In powder coating, the object being coated is grounded to provide a direct path for the electrostatic charge to flow. The charged powder particles are drawn to the grounded surface, ensuring a uniform coating. Proper grounding is crucial for achieving a high-quality finish and ensuring the correct film build on the part.

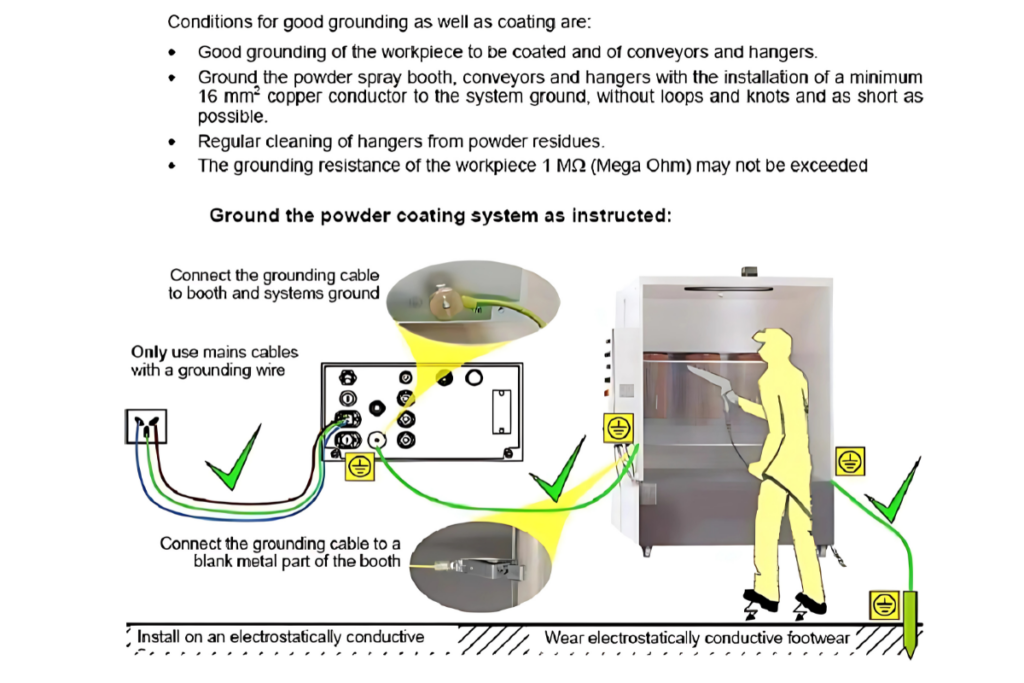

Key components of proper grounding include:

- Grounding cables connected to the powder coating booth

- Properly grounded hooks made from conductive materials like steel

- Electrostatic conductive footwear to ensure operator safety

- Operators should use bare hands to handle the gun, as the gun’s handle is made from conductive material, or use gloves with conductive properties.

The Role of Clean Hooks in Grounding

To maintain effective grounding, it is critical that hooks are kept clean and free from rust, paint buildup, or any other contaminants. Hooks with a coating of paint may not provide proper grounding. For effective grounding, the hook must make direct contact with the part, allowing metal-to-metal contact. Any layer of cured paint or powder on the hook or part acts as an insulator, preventing proper grounding.

Proper grounding will improve transfer efficiency, saving both time and materials in your coating process. Dirty or coated hooks can interfere with the electrostatic charge, leading to uneven coating and low film builds. At ACR Hooks, our hooks are made from high-quality Canadian steel, ensuring a reliable and strong connection for the grounding process.

Ensure your powder coating process is efficient and effective. Contact us for more information or to place an order for our high-quality grounding hooks!